You Are Here:Home> Product display

>Fluororubber/Fluorosilicone oil

Fluororubber Powder

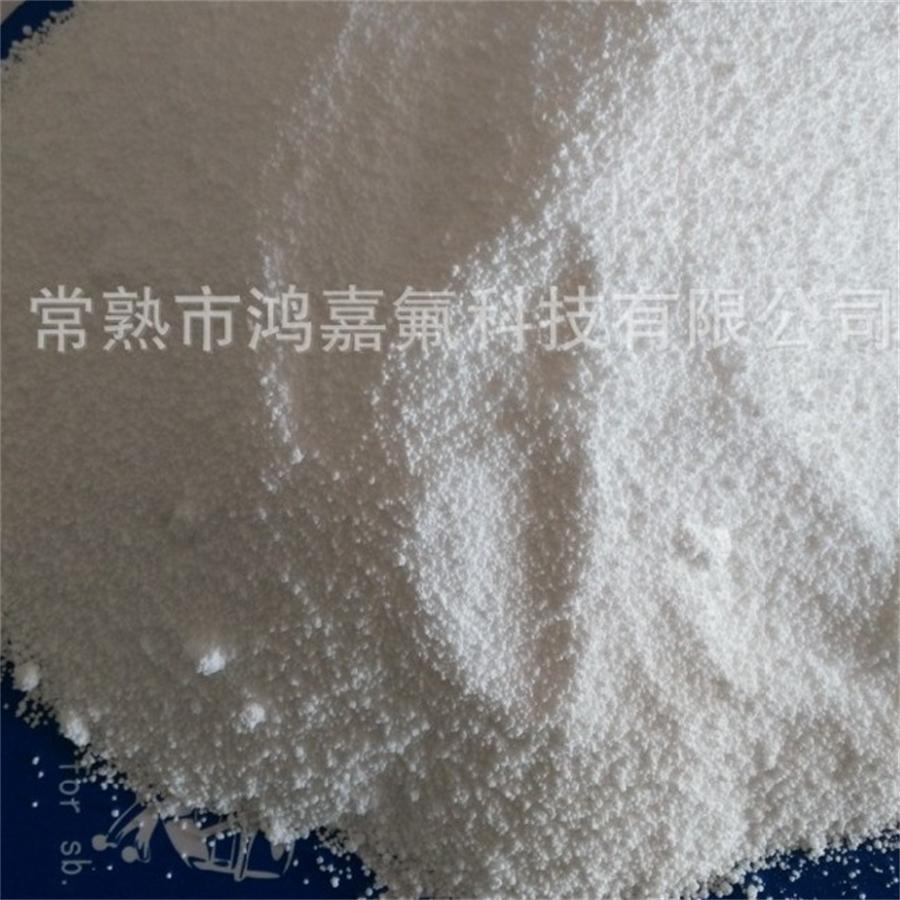

Powdered fluororubber is an additive based on free flowing fluorinated polymers. It is a white free flowing powder used to improve the processing performance of thermoplastic plastics at a very low dosage (500-1500ppm). It can add various plastic particles to achieve chemical resistance, high temperature resistance, flame retardant effect, and will not affect the physical properties of the resin i

PPA 2626 Fluoroelastomer Powder Polymer Processing Aid

Product Introduction

Product Form

Physical Properties

Product Functions

Performance

Applications

Processing Guidelines

Storage Method

Packaging Specification

Prev: Fluororubber

Next: Lithium Fluoride

Website Navigation

Contact Us

- Company Address: Fluorination Technology Park, Changshu City, Jiangsu Province

- Service Hotline: 0512-52818267

- Technical Consultation: 0512-52626090

- Contact phone number: 13601573215

- Company email: xlu113549@gmail.com

+

wechat number:weiixnhao

wechat number:weiixnhao

wechat number:weiixnhao

wechat number:weiixnhao

Copy WeChat to WeChat

苏公网安备32058102001807号

苏公网安备32058102001807号 Home

Home

WeChat

WeChat

Tell

Tell