Sodium Perfluorononenoxybenzenesulfonate

Perfluorononenoxybenzenesulfonate sodium (OBS for short in China) is an anionic fluorinated surfactant with high cost-effectiveness, high surface activity, excellent chemical resistance, and good water and oil repellency. Widely used in detergents, latex, coatings, pigment additives, emulsifiers, dispersants, wetting agents, fluoroprotein fire extinguishers, petroleum displacement agents, oil coll

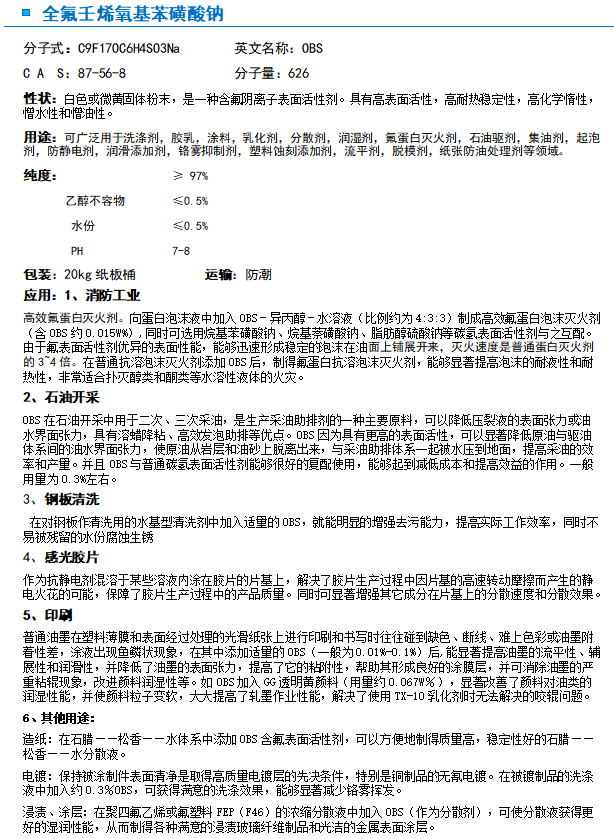

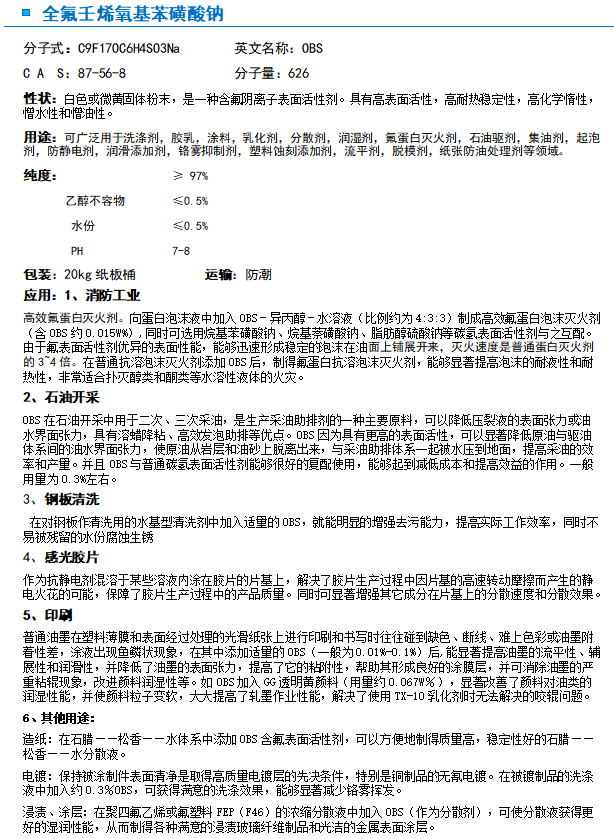

Perfluorononenoxybenzenesulfonate Sodium

-

Molecular Formula: C₁₉F₁₇O₆H₃SNa

-

English Name: OBS

-

CAS No.: 87-56-8

-

Molecular Weight: 626

Properties: White or pale yellow powder, a perfluoro anionic surfactant. It has high surface activity, high heat resistance stability, high chemical inertness, hydrophobicity and oleophobicity.

Applications: Widely used in detergents, degreasing, coatings, emulsifiers, dispersants, wetting agents, fluoroprotein fire extinguishers, petroleum demulsifiers, oil collectors, foaming agents, antistatic agents, lubricant additives, tin plating inhibitors, plastic etching additives, leveling agents, mold release agents, paper oil-proof treatment, etc.

Purity:

-

≥97%

-

Ethanol-insoluble Substances: ≤0.5%

-

Moisture: ≤0.5%

-

pH: 7-8

Packaging: 20kg cardboard drum

Transportation: Moisture-proof

Applications:

-

Fire Protection Industry

High-efficiency fluoroprotein fire extinguishing agent: Add OBS-isopropanol-water solution (ratio ~4:3:3) to foam liquid to make high-concentration fluoroprotein foam fire extinguishing agent (containing ~0.108% OBS). It can also be mixed with hydrocarbon surfactants such as sodium alkylbenzene sulfonate, sodium alkylnaphthalene sulfonate, and sodium fatty alcohol sulfate. Due to the excellent surface properties of fluorosurfactants, the stable foam spreads on the oil surface, and the fire-extinguishing speed is 3-4 times that of ordinary protein fire extinguishing agents. Adding OBS to ordinary fluoroprotein fire extinguishing agents produces fluoroprotein anti-solvent foam fire extinguishing agents, which significantly improve the liquid resistance and heat resistance of the foam, suitable for extinguishing fires of water-soluble liquids such as alcohols and esters.

-

Petroleum Exploitation

Used in secondary and tertiary oil recovery, it is one of the main raw materials for oil recovery cleanup additives. It can reduce the surface tension of fracturing fluid and oil-water interfacial tension, with advantages such as cleanup and drag reduction, and high-efficiency foaming cleanup. OBS has stronger surface activity, which can reduce the oil-water interfacial tension between crude oil and the flooding system, making crude oil separate from rock formations and sediment, forming an oil-in-water system to be pressed to the surface, improving oil recovery efficiency and output. OBS can be well compounded with ordinary hydrocarbon surfactants, reducing costs and improving benefits, with a general dosage of about 0.3%.

-

Steel Plate Cleaning

Adding an appropriate amount of OBS to water-based cleaning agents for steel plate storage can significantly enhance decontamination ability, improve work efficiency, and not easily damage the rust-proof performance of steel plates.

-

Photosensitive Film

As an antistatic agent mixed in some solutions and coated on film substrates, it solves the problem of electrostatic sparks caused by high-speed rotational friction in film production, ensuring product quality. It also enhances the dispersion speed and effect of other components on the substrate.

-

Printing

Ordinary inks often have defects such as discoloration, broken lines, and color stacking when printing on plastic films and treated smooth paper. OBS (generally 0.01%-0.1%) can significantly improve the leveling, adhesion and gloss of the ink. For example, adding OBS to the ink can reduce ink stacking and ghosting, improve ink wettability; or compounded with transparent yellow pigments, it can improve pigment wettability, enhance ink colorability, and solve printing failure problems.

-

Other Uses

-

Continuous paper: Adding OBS surfactants to the paraffin-rosin-water system can prepare paraffin-rosin-water dispersions with high coverage and good stability.

-

Electroplating: Keeping the surface of plated parts clean is a prerequisite for high-quality electroplating layers. Adding about 0.3% OBS to the bright plating solution for copper products can obtain satisfactory brightening effects and reduce plating solution fog.

-

Inks and coatings: Adding OBS (as a dispersant) to the concentrated dispersion of tetrafluoroethylene or fluoroplastics (FEP) can improve the wettability and spreadability of the dispersion, allowing it to obtain a thicker metal surface coating.

wechat number:weiixnhao

wechat number:weiixnhao

wechat number:weiixnhao

wechat number:weiixnhao

苏公网安备32058102001807号

苏公网安备32058102001807号 Home

Home

WeChat

WeChat

Tell

Tell