Perfluoro(4-methylpent-2ene)

Hexafluoropropylene dimer, chemical name perfluoro (4-methyl-2-pentene). Dual phase immersion electronic coolant, which can be used for cleaning large electrical equipment and data centers, is a commonly used electronic fluorine liquid. Low surface tension, low boiling point. Has good environmental performance, electrical insulation, safety and energy saving.

Product Appearance: Colorless, odorless, transparent liquid

Boiling Point (Atmospheric Pressure): 47℃

Liquid Density (25℃): 1.601g/mL

Dielectric Strength (3mm): 78.9kV

Dielectric Constant (12GHz): 1.88

Resistivity: 3.070×10¹⁵Ω·mm

Surface Tension (25℃): 11.44mN/m

Viscosity (25℃): 0.3562cst

Maximum Operating Temperature: 400℃

ODP : 0

GWP : 20

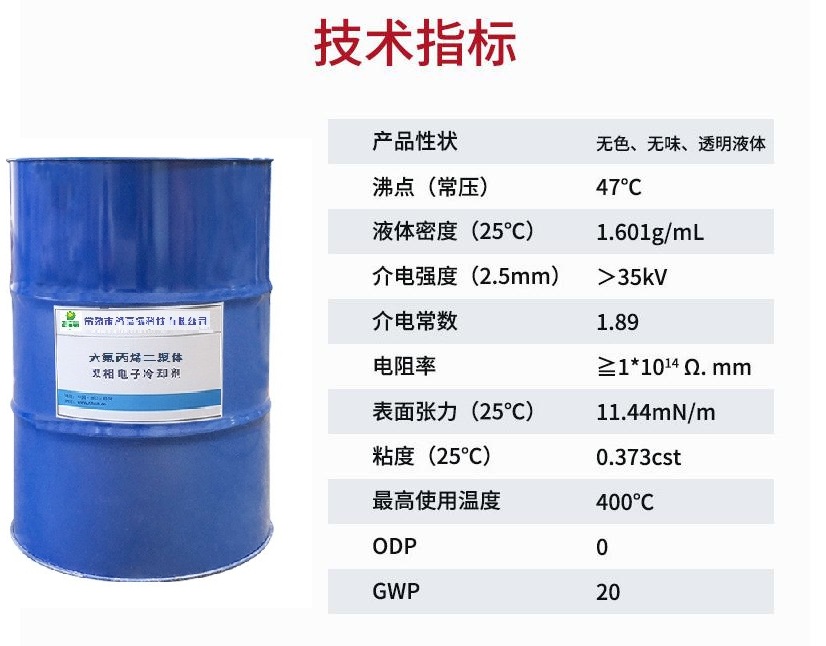

Product Appearance: Colorless, odorless, transparent liquid

Boiling Point (Atmospheric Pressure): 47℃

Liquid Density (25℃): 1.601g/mL

Dielectric Strength (2.5mm): >35kV

Dielectric Constant: 1.89

Resistivity: ≥1×10¹⁴Ω·mm

Surface Tension (25℃): 11.44mN/m

Viscosity (25℃): 0.373cst

Maximum Operating Temperature: 400℃

ODP : 0

GWP : 20

Product Advantages

Excellent environmental performance: ODP value is 0, GWP value is 20; it is environmentally friendly, non-toxic, harmless and non-irritating

High-efficiency electrical insulation performance: Non-conductive and non-flammable, with a dielectric strength of 78.9kV, which will not damage precision electronic instruments and equipment

Good safety performance in use: It is liquid at room temperature (a common chemical), with LC50>22600mg/m³, so it has good safety in use

Better energy saving and consumption reduction: Phase-change latent heat dissipation is more efficient, making it more suitable for heat dissipation scenarios of large TDP chips (such as supercomputing centers)

What is Two-Phase Immersion Cooling

Two-phase immersion cooling generally uses coolants with low boiling points, high dielectric constants, good insulation, ideal chemical inertness, excellent thermal conductivity, and good system compatibility. After the coolant takes away the heat of the server, it undergoes phase change and vaporization; the gaseous coolant is then condensed by the condenser and turns back into liquid to return to the liquid cooling tank. Phase-change cooling can exponentially improve the heat transfer efficiency of the liquid, so as to achieve rapid and stable cooling as well as energy saving and consumption reduction. It is generally suitable for heat dissipation scenarios of large TDP chips.

Website Navigation

Contact Us

- Company Address: Fluorination Technology Park, Changshu City, Jiangsu Province

- Service Hotline: 0512-52818267

- Technical Consultation: 0512-52626090

- Contact phone number: 13601573215

- Company email: xlu113549@gmail.com

wechat number:weiixnhao

wechat number:weiixnhao

Copy WeChat to WeChat

苏公网安备32058102001807号

苏公网安备32058102001807号 Home

Home

WeChat

WeChat

Tell

Tell